Projects

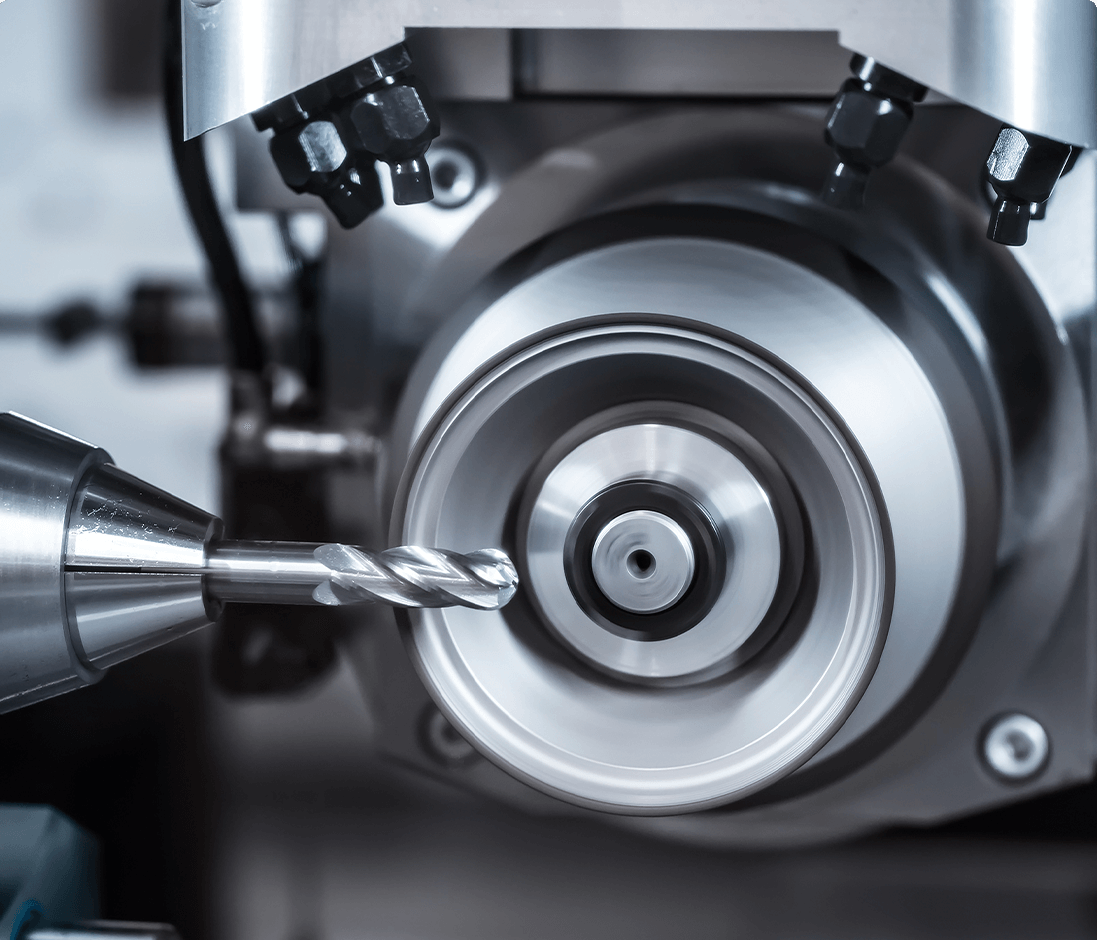

Here are just a few examples of the innovative solutions and value added products and services that we deliver every day

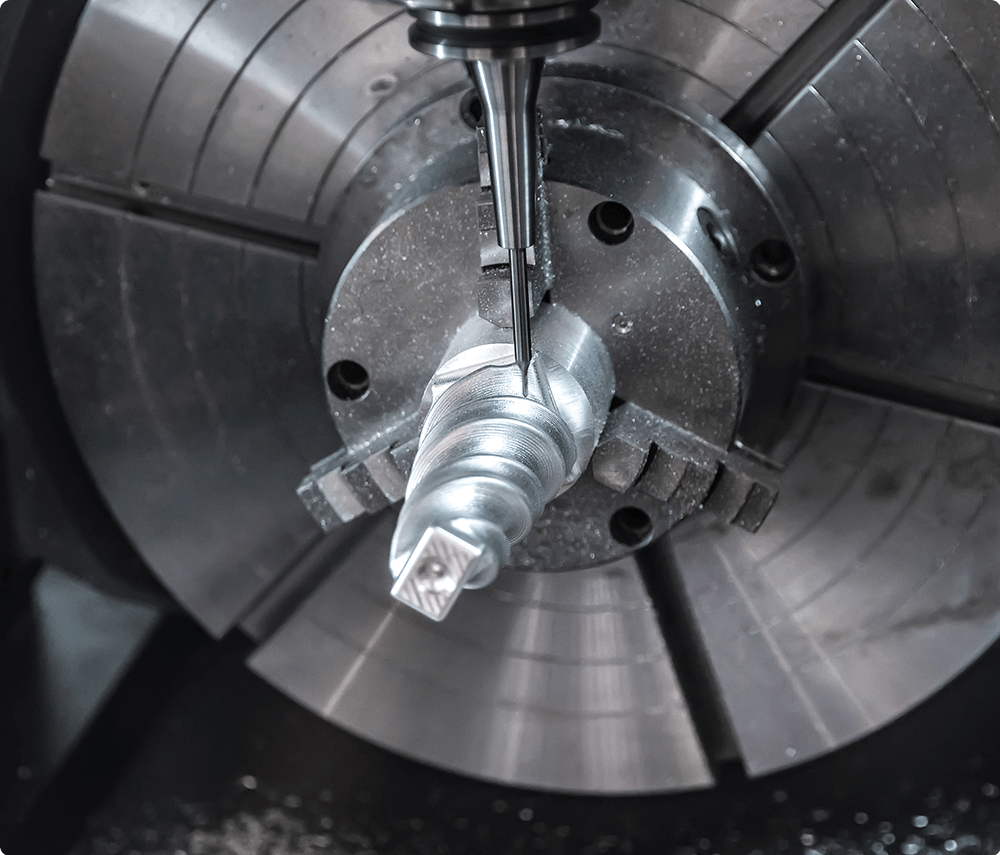

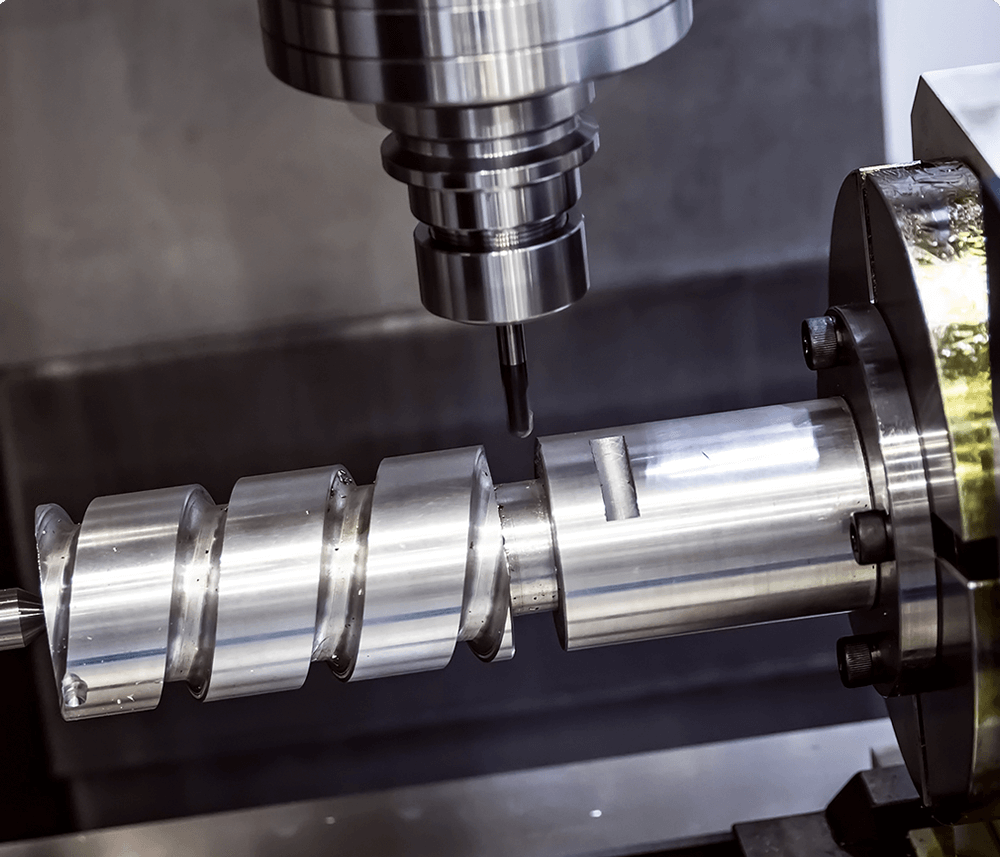

CNC Turning of Titanium Studded Threaded Fasteners for the Military Industry

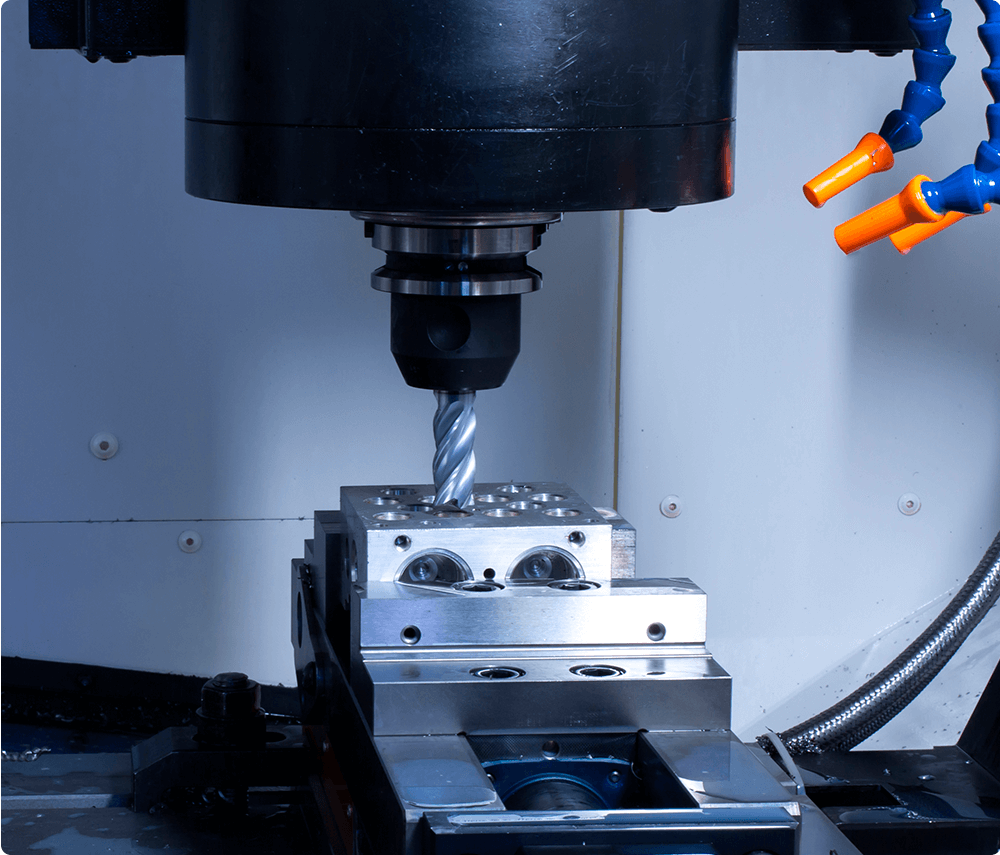

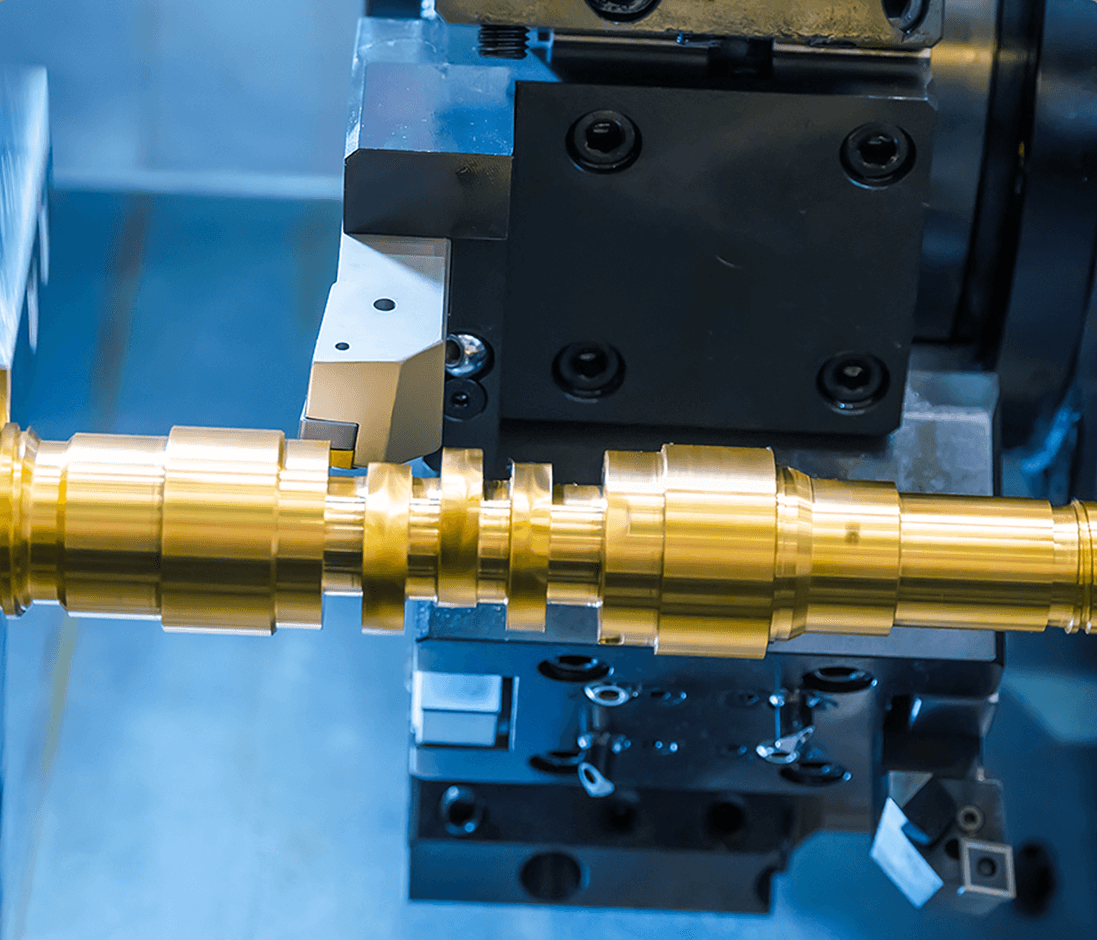

CNC Swiss Lathe Machining of a Compressor Head Component for the HVAC Industry

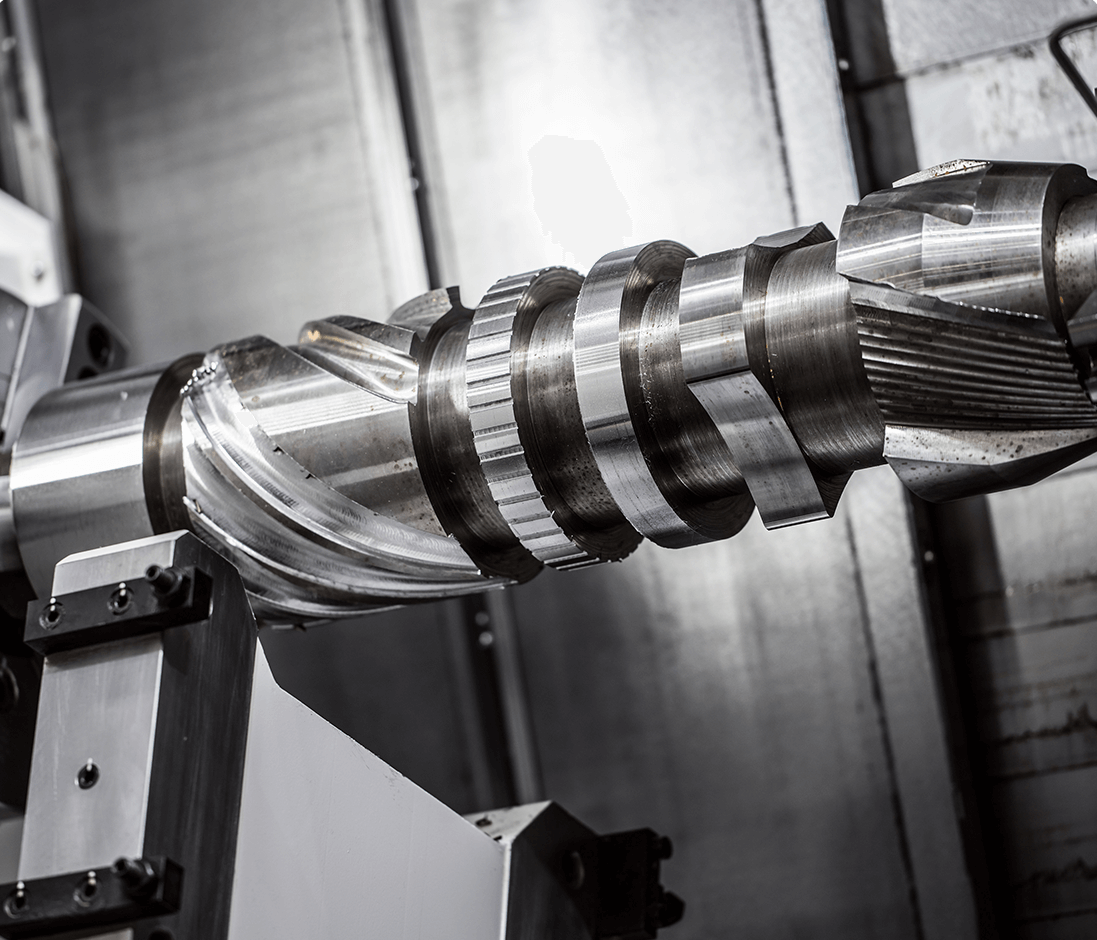

Manufacturing of a Cold Roll Steel Pedestal for the Food Equipment Industry

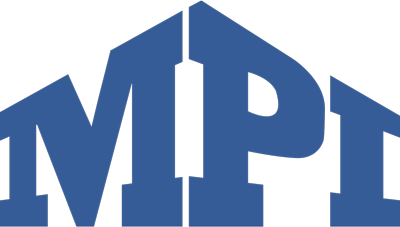

Milling & Painting of an Aluminum Valve Cover for the Forklift Industry

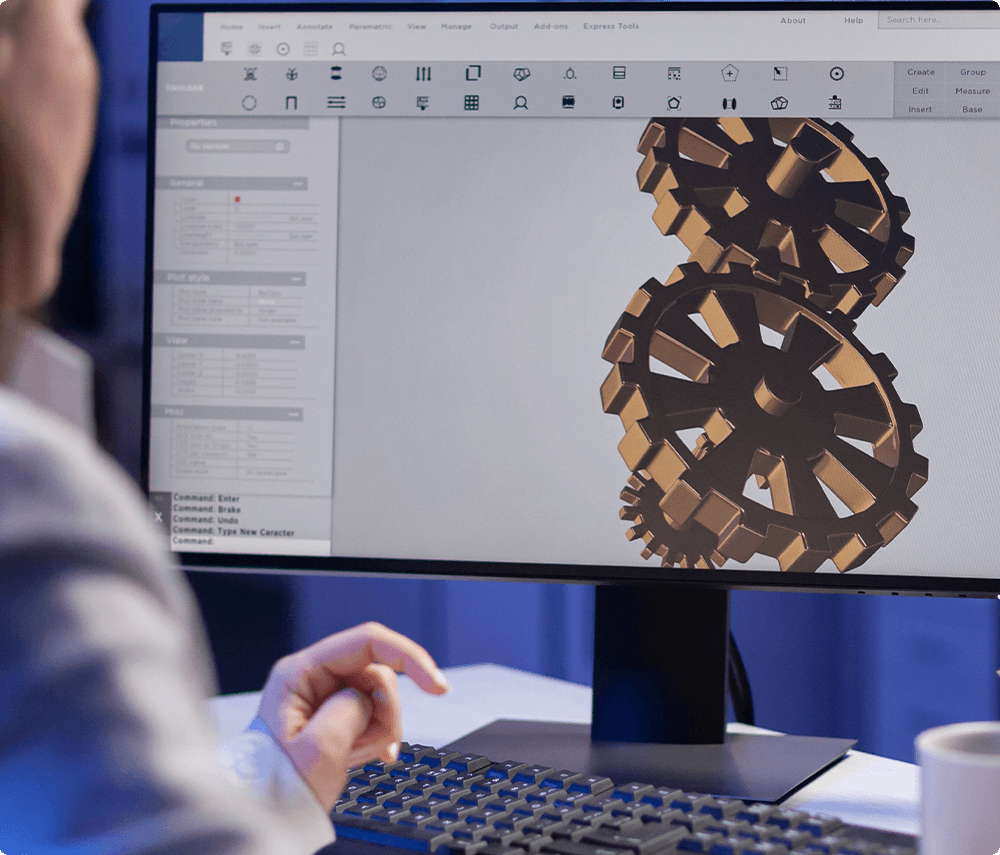

About us

Full Service Manufacturing Since 1988

Since 1988, a commitment to delivering precision machined products and superior manufacturing services has enabled Miller Precision Manufacturing Industries (MPI) to grow from a small job shop to a full-service manufacturing facility serving the machined product needs of industries ranging from appliances to lift trucks to plastics.

With years of engineering and technological experience, we can provide a total solution for all of your machined product needs: production, part identification, inventory management, and distribution.

At MPI, our goal is to consistently meet and exceed customer expectations for guaranteed success of your machined products program. From concept to finished product, MPI is your partner in quality.